Strabag executing ‘largest’ project using its ‘quiet, less pollutant’ asphalt

19 September 2024

Strabag – Austria’s largest construction company – announced it’s using an “air-purifying” and “noise-absorbing” asphalt for road works on Erbschlöer Straße in Wuppertal, Germany.

Workers roll the Clean Air Asphalt into place. (Image: Strabag)

Workers roll the Clean Air Asphalt into place. (Image: Strabag)

Called Clean Air Asphalt, stylised ClAir for short, Strabag said it is renovating the surface course of a 1km stretch of road with a total area around 11,300m2.

The company added it’s the largest ClAir project to date of the 20 pilot routes executed to date. ClAir was first launched in Germany in 2019.

“In the past few days, the Strabag team from the North Rhine-Westphalia Directorate has installed a total of around 1,100 tonnes of Clean Air Asphalt on Erbschlöer Straße, which is around 11m wide, with the company’s innovation manufacturer,” said Strabag. “Previously, the construction site team of the Rhineland… milled off the old asphalt layers and renewed the binder course since 29 July, first on the uphill side of the road, then on the downhill side of the road.”

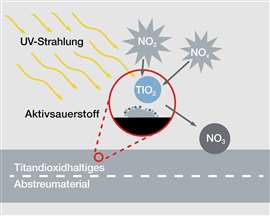

The material relies on titanium dioxide (TiO2), which produces a photocatalytic effect that ultimately helps reduce nitrogen dioxide (NO2) under ideal conditions (ample sun, little wind). TiO2 is a mineral which exists naturally in sands, soils and other minerals, but can also be synthetically produced from natural ores like ilmenite and rutile.

“The spreading material used with TiO2-offset ultra-high-performance concrete (UHPC) builds nitrogen oxides bound in the air under the influence of UV radiation and converts them into harmless nitrates,” explained Strabag. “The spreading granules are directly and permanently integrated into the hot asphalt surface using a paving process developed by the Strabag Competence Centre, TPA.”

Strabag said TPA is using a complex method to track NO2 emissions.

Image of the photocatalytic process that Strabag says reduces nitrogen dioxide in the asphalt-laying process. (Image: Strabag)

Image of the photocatalytic process that Strabag says reduces nitrogen dioxide in the asphalt-laying process. (Image: Strabag)

“TPA installed two so-called passive collectors on Erbschlöer Straße before the start of the construction project,” said Strabag. “Since then, the NO2-absorbing tubes in the collectors have been replaced monthly and sent to a laboratory for evaluation.

“Over time, it will be possible to deduce from the values collected to what extent the Clean Air Asphalt on Erbschlöer Straße has reduced the nitrogen dioxide concentration in the air.”

Noise-reduction an added benefit of ClAir Asphalt

Strabag noted noise-reduction applies after installation.

“[It] dampens tire rolling noise due to its special texture,” said Strabag, which noted testing to pilot tracks revealed decibel-reduction between 2 and 4 db(A). “In terms of acoustic perception, this corresponds to a decrease in traffic volume of up to 50% and is comparable to specially designed noise-optimised asphalt surfaces.”

Additional testing and monitoring is planned for the Wuppertal project, which it will compare with initial decibel measurements taken on Erbschlöer Straße in May.

A close up look of the Clean Air Asphalt from Strabag as its distributed to the road surface. (Image: Strabag)

A close up look of the Clean Air Asphalt from Strabag as its distributed to the road surface. (Image: Strabag)

CONECTAR-SE COM A EQUIPE